| Simple to complex: a molecular perspective

Modern synthetic chemistry has reached the point where it is possible to prepare small molecules to almost any structure. These methods are used today to produce a wide variety of useful chemicals such as pharmaceuticals or commercial polymers. The ability of this is to extend the control to the next, seeking methods to assemble these single molecules into supramolecular assemblies consisting of many molecules arranged in a well defined manner.

These approaches utilize the concepts of molecular self-assembly and/or supramolecular chemistry to automatically arrange themselves into some useful conformation through a bottom-up approach. The concept of molecular recognition is especially important: molecules can be designed so that a specific conformation or arrangement is favored due to non-covalent intermolecular forces. The Watson-Crick basepairing rules are a direct result of this, as is the specificity of an enzyme being targeted to a single substrate, or the specific folding of the protein itself. Thus, two or more components can be designed to be complementary and mutually attractive so that they make a more complex and useful whole.

Such bottom-up approaches should, broadly speaking, be able to produce devices in parallel and much cheaper than top-down methods, but could potentially be overwhelmed as the size and complexity of the desired assembly increases. However, the bottom-up approach is viewed by many thoughtful scientists as being mostly wishful thinking. Most useful structures require complex and thermodynamically unlikely arrangements of atoms. The basic laws of probability and entropy make it very unlikely that atoms will "self-assemble" in useful configurations, or can be easily and economically nudged to do so. About the only example of this is crystal-growing, for which Nanotechnology cannot take any credit, it having been around for millenia.

Molecular Nanotechnology: a long-term view

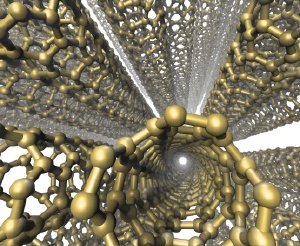

Advanced nanotechnology, sometimes called molecular manufacturing, is a term given to the concept of engineered nanosystems (nanoscale machines) operating on the molecular scale. By the countless examples found in biology it is currently known that billions of years of evolutionary feedback can produce sophisticated, stochastically optimized biological machines, and it is hoped that developments in nanotechnology will make possible their construction by some shorter means, perhaps using biomimetic principles. However, K Eric Drexler and other researchers have proposed that advanced nanotechnology, although perhaps initially implemented by biomimetic means, ultimately could be based on mechanical engineering principles (see also mechanosynthesis)

When the term "nanotechnology" was independently coined and popularized by Eric Drexler, who at the time was unaware of an earlier usage by Norio Taniguchi, it referred to a future manufacturing technology based on molecular machine systems. The premise was that molecular-scale biological analogies of traditional machine components demonstrated that molecular machines were possible, and that a manufacturing technology based on the mechanical functionality of these components (such as gears, bearings, motors, and structural members) would enable programmable, positional assembly to atomic specification (see the original reference PNAS-1981). The physics and engineering performance of exemplar designs were analyzed in the textbook Nanosystems.

Another view, put forth by Carlo Montemagno, is that future nanosystems will be hybrids of silicon technology and biological molecular machines, and his group's research is directed toward this end.

The seminal experiment proving that positional molecular assembly is possible was performed by Ho and Lee at Cornell University in 1999. They used a scanning tunneling microscope to move an individual carbon monoxide molecule (CO) to an individual iron atom (Fe) sitting on a flat silver crystal, and chemically bound the CO to the Fe by applying a voltage.

Though biology clearly demonstrates that molecular machine systems are possible, non-biological molecular machines are today only in their infancy. Leaders in research on non-biological molecular machines are Dr. Alex Zettl and his colleagues at Lawrence Berkeley Laboratories and UC Berkeley. They have constructed at least three distinct molecular devices whose motion is controlled from the desktop with changing voltage: a nanotube nanomotor, a molecular actuator, and a nanoelectromechanical relaxation oscillator.

Manufacturing in the context of productive nanosystems is not related to, and should be clearly distinguished from, the conventional technologies used to manufacture nanomaterials such as carbon nanotubes and nanoparticles.

There exists the potential to design and fabricate artificial structures analogous to natural cells and even organisms. Note that these are just blue-sky "potentials", and fall closer to the disciplines of Applied Biology and gene-splicing than to Nanotechnology.

Current research

As nanotechnology is a very broad term, there are many disparate but sometimes overlapping subfields that could fall under its umbrella. The following avenues of research could be considered subfields of nanotechnology. Note that these categories are fairly nebulous and a single subfield may overlap many of them, especially as the field of nanotechnology continues to mature.

Nanomaterials

This includes subfields which develop or study materials having unique properties arising from their nanoscale dimensions.

Bottom-up approaches

| - |

Colloid science has given rise to many materials which may be useful in nanotechnology, such as carbon nanotubes and other fullerenes, and various nanoparticles and nanorods. |

| - |

Nanoscale materials can also be used for bulk applications; most present commercial applications of nanotechnology are of this flavor. |

| - |

Headway has been made in using these materials for medical applications; see Nanomedicine. |

These seek to arrange smaller components into more complex assemblies.

-

DNA Nanotechnology utilizes the specificity of Watson-Crick basepairing to construct well-defined structures out of DNA and other nucleic acids.

-

More generally, molecular self-assembly seeks to use concepts of supramolecular chemistry, and molecular recognition in particular, to cause single-molecule components to automatically arrange themselves into some useful conformation.

Top-down approaches

These seek to create smaller devices by using larger ones to direct their assembly.

-

Many technologies descended from conventional solid-state silicon methods for fabricating microprocessors are now capable of creating features smaller than 100 nm, falling under the definition of nanotechnology. Giant magnetoresistance-based hard drives already on the market fit this description, as do atomic layer deposition (ALD) techniques.

-

Solid-state techniques can also be used to create devices known as nanoelectromechanical systems or NEMS, which are related to microelectromechanical systems or MEMS.

-

Atomic force microscope tips can be used as a nanoscale "write head" to deposit a chemical on a surface in a desired pattern in a process called dip pen nanolithography. This fits into the larger subfield of nanolithography.

Functional approaches

These seek to develop components of a desired functionality without regard to how they might be assembled.

-

Molecular electronics seeks to develop molecules with useful electronic properties. These could then be used as single-molecule components in a nanoelectronic device. For an example see rotaxane.

-

Synthetic chemical methods can also be used to create synthetic molecular motors, such as in a so-called nanocar.

Speculative

These subfields seek to anticipate what inventions nanotechnology might yield, or attempt to propose an agenda along which inquiry might progress. These often take a big-picture view of nanotechnology, with more emphasis on its societal implications than the details of how such inventions could actually be created.

-

Molecular nanotechnology is a proposed approach which involves manipulating single molecules in finely controlled, deterministic ways. This is more theoretical than the other subfields and is beyond current capabilities.

-

Nanorobotics centers on self-sufficient machines of some functionality operating at the nanoscale.

-

Programmable matter based on artificial atoms seeks to design materials whose properties can be easily and reversibly externally controlled.

Tools and techniques

Typical AFM setup. A microfabricated cantilever with a sharp tip is deflected by features on a sample surface, much like in a phonograph but on a much smaller scale. A laser beam reflects off the backside of the cantilever into a set of photodetectors, allowing the deflection to be measured and assembled into an image of the surface.

Nanoscience and nanotechnology only became possible in the 1910's with the development of the first tools to measure and make nanostructures. But the actual development started with the discovery of electrons and neutrons which showed scientists that matter can really exist on a much smaller scale than what we normally think of as small, and/or what they thought was possible at the time. It was at this time when curiosity for nanostructures had originated.

The atomic force microscope (AFM) and the Scanning Tunneling Microscope (STM) are two early versions of scanning probes that launched nanotechnology. There are other types of scanning probe microscopy, all based on the idea of the STM, that make it possible to see structures at the nanoscale. The tip of scanning probes can also be used to manipulate nanostructures (a process called positional assembly). However, this is a very slow process. This led to the development of various techniques of nanolithography such as dip pen nanolithography, electron beam lithography or nanoimprint lithography. Lithography is a top-down fabrication technique where a bulk material is reduced in size to nanoscale pattern.

The top-down approach anticipates nanodevices that must be built piece by piece in stages, much as manufactured items are currently made. Scanning probe microscopy is an important technique both for characterization and synthesis of nanomaterials. Atomic force microscopes and scanning tunneling microscopes can be used to look at surfaces and to move atoms around. By designing different tips for these microscopes, they can be used for carving out structures on surfaces and to help guide self-assembling structures. Atoms can be moved around on a surface with scanning probe microscopy techniques, but it is cumbersome, expensive and very time-consuming. For these reasons, it is not feasible to construct nanoscaled devices atom by atom. Assembling a billion transistor microchip at the rate of about one transistor an hour is inefficient.

One hope is that these techniques may eventually be used to make primitive nanomachines, which in turn can be used to make more sophisticated nanomachines. But the whole nanomachine concept is wild speculation, as we are unable to even conceptually design human scale machines that can independently make other machines. If we can't make them on a convenient scale, what are the chances they can be made on a nano scale? Also nanomachines have the very substantial hurdles of friction and surface-tension.

In contrast, bottom-up techniques build or grow larger structures atom by atom or molecule by molecule. These techniques include chemical synthesis, self-assembly and positional assembly. Another variation of the bottom-up approach is molecular beam epitaxy or MBE. Researchers at Bell Telephone Laboratories like John R. Arthur. Alfred Y. Cho, and Art C. Gossard developed and implemented MBE as a research tool in the late 1960s and 1970s. Samples made by MBE were key to to the discovery of the fractional quantum Hall effect for which the 1998 Nobel Prize in Physics was awarded. MBE allows scientists to lay down atomically-precise layers of atoms and, in the process, build up complex structures. Important for research on semiconductors, MBE is also widely used to make samples and devices for the newly emerging field of spintronics.

Newer techniques such as Dual Polarisation Interferometry are enabling scientists to measure quantitatively the molecular interactions that take place at the nano-scale.

Societal implications

Potential risks of nanotechnology can broadly be grouped into three areas:

Nanoethics concerns the ethical and social issues associated with developments in nanotechnology, a science which encompass several fields of science and engineering, including biology, chemistry, computing, and materials science. Nanotechnology refers to the manipulation of very small-scale matter – a nanometer is one billionth of a meter, and nanotechnology is generally used to mean work on matter at 100 nanometers and smaller.

Social risks related to nanotechnology development include the possibility of military applications of nanotechnology (such as implants and other means for soldier enhancement) as well as enhanced surveillance capabilities through nano-sensors. However those applications still belong to science-fiction and will not be possible in the next decades. Significant environmental, health, and safety issues might arise with development in nanotechnology since some negative effects of nanoparticles in our environment might be overlooked. However nature itself creates all kinds of nanoobjects, so probable dangers are not due to the nanoscale alone, but due to the fact that toxic materials become more harmful when ingested or inhaled as nanoparticles. |